Pavement Collection

Customizable Pavement Data Collection

Mandli’s Collection Technology: LCMS-2

The state-of-the-art Laser Crack Measurement System, LCMS-2:

- Scans a 13-foot wide swath in a single pass, saving time and money.

- LCMS-2 utilizes automated lane detection to produce more repeatable longitudinal profiles compared to legacy profilers. Traditional profiling methods are susceptible to driver wander, making historical analysis unreliable.

- Distress, condition, and roadway geometry metrics are linked to global position coordinates and location reference systems (LRS) facilitating robust historical comparison of pavement section performance.

- LCMS-2 operates in all lighting conditions and gets accurate data at survey speeds up to 70 mph. This eliminates the need for walking surveys, reducing risk and eliminating traffic disruption.

- The LCMS-2 meets or exceeds all current and relevant ASTM and AASHTO industry standards for pavement condition assessment.

The LCMS-2 Advantage:

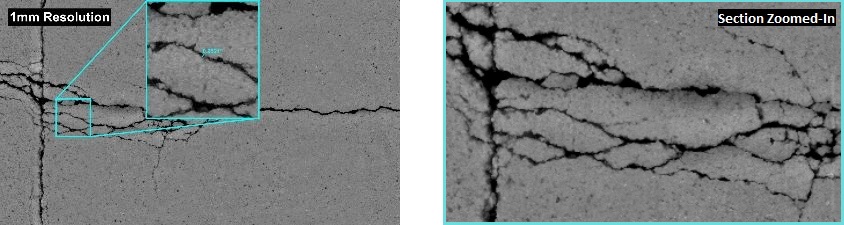

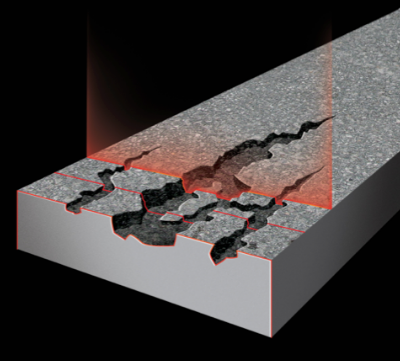

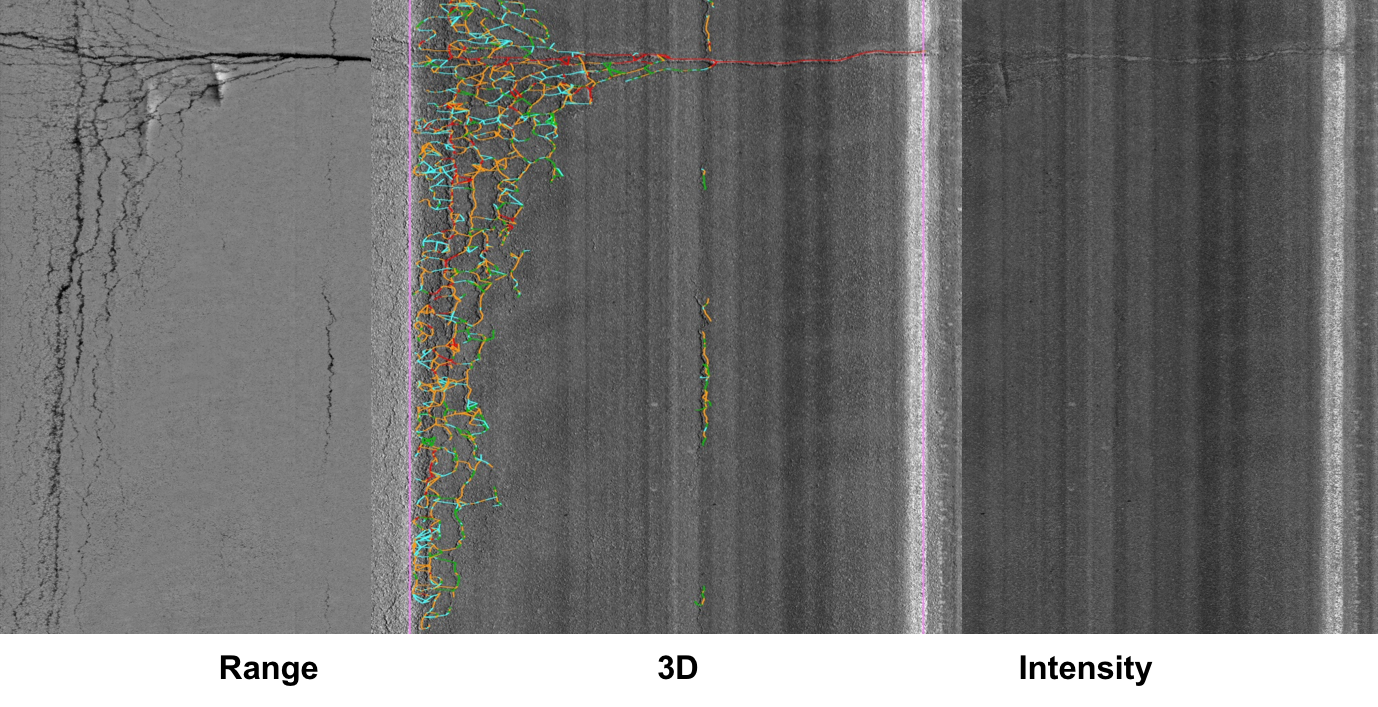

1. Collect 2D & 3D Images

With a configurable scan resolution of 1-5mm and 0.05mm vertical resolution, the LCMS-2 acquires detailed range and intensity data. When combined through post-processing, the resulting images and 3D data allow for automated distress detection and visual analysis.

- 2D images provide a continuous representation of pavement condition for visual analysis allowing users to “revisit” a pavement section remotely.

- 3D data accurately represents distress depth and width for automated distress detection and classification.

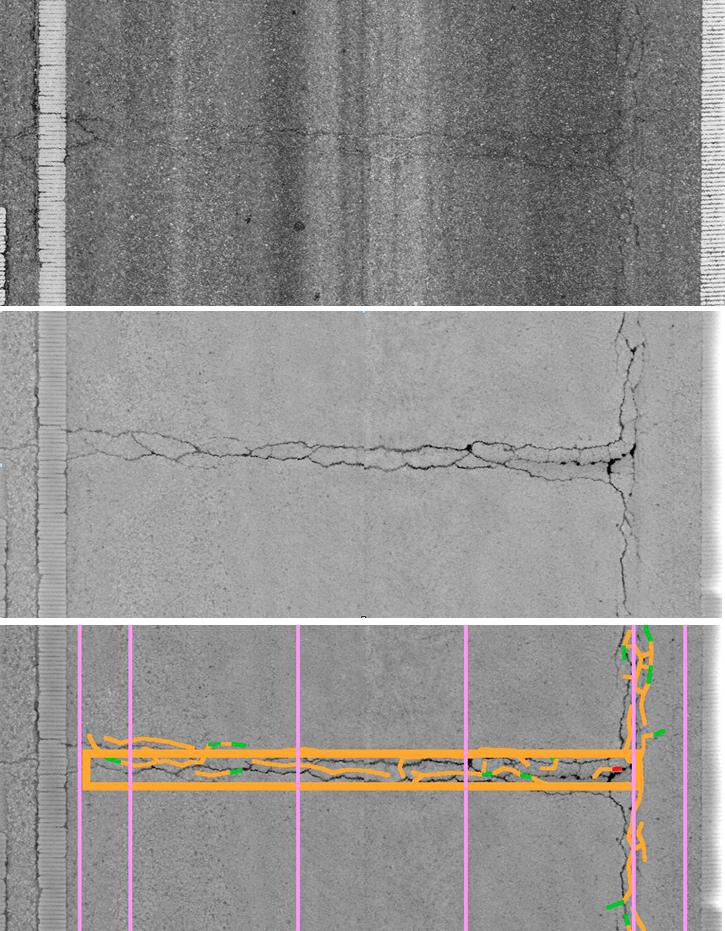

2. Automated Crack Identification

LCMS-2 captures a multitude of pavement details in a single pass, giving users the ability to customize outputs, and even allowing for subsequent extraction of additional details. The automated distress detection and classification increases repeatability results beyond what is obtained through manual rating survey methods. The ability to produce repeatable results over subsequent collection cycles provides greater confidence in historical comparisons.

Key functional parameters that can be automatically detected and measured include:

- Cracking (both sealed and unsealed)

- Roughness (IRI)

- Rutting

- Potholes

- Raveling (an industry first)

- Macro-texture (MPD, MTD) in all 5 AASHTO bands

- Bleeding

- Faulting

- Delamination

- Shoving

- Edge drop off and curb

- Joints

- Pavement type (asphalt, chipseal, porous, concrete)

- Pavement markings

- Rumble strips

- Cross Slope

3. International Roughness Index (IRI) Reporting

LCMS-2 is able to produce, collect, and report accurate and repeatable IRI data. Automated lane detection, based on pavement striping, ensures IRI is consistently sampled in the wheel paths, eliminating erroneous measurements caused by poor lane position and driver wander.

4. Laser Digital Terrain Mapping (LDTM)

With high-resolution (1mm) downward images, the LCMS detects road edges, lane markings, and curbs for LDTM. With the slope, curvature, and crossfall measurements, roadway designers can use the information for an as-built digital model rather than relying on traditional surveying techniques, saving both time and money.

The video below shows Mandli’s LDTM product:

Automatic Pavement Distress Software

Two separate software applications are utilized to analyze the collected data and automatically detect pavement distresses.

- Data is first run through RoadAnalyser

- Cracks are automatically detected and assigned width by analyzing the intensity and range data.

- Outputs four sets of viewable images: Range, intensity, and both range and intensity with detected distress overlay.

- Data is then run through Mandli’s internally developed classifier application.

- Marked cracks are analyzed and classified according to the client specifications. Rutting and transverse profile information is also processed and reported.

- Cracks are automatically detected and assigned width by analyzing the intensity and range data.

Data is Georeferenced for Accuracy

Our Position Orientation System (POS) includes a complex GPS/IMU/DMI system that works simultaneously to continually report the best possible position.

With poor satellite coverage, the IMU will take over the bulk of the positioning workload, with IMU working at a high rate, around 100-2,000 Hz, or 100-2,000 times per second. The distance measurement indicator (DMI) reports the distance traveled to further improve GPS/IMU processing.

Pavement Management

Once data is collected, it is available for further analysis.

- Our clients can come back after an initial analysis and request further information.

- Post-processing parameters are configurable and customizable. We work with our clients to examine different parameters of their pavement.

- We can also make the data and the analysis available to multiple departments.

- If you are interested in working with us, please reach out to one of our representatives for more information.