Transportation

Mandli offers a variety of comprehensive mobile solutions for transportation infrastructure management applications. By integrating the latest and most advanced data collection hardware, Mandli provides clients with efficient and cost-effective systems and services.

Highway

Urban Modeling | Asset Inventory | Intersection Modeling | Asset Encroachment | Right-of-Way Imaging | Curve and Grade | Real-Time Differential GPS | Clearances | Sign Retroreflectivity Data

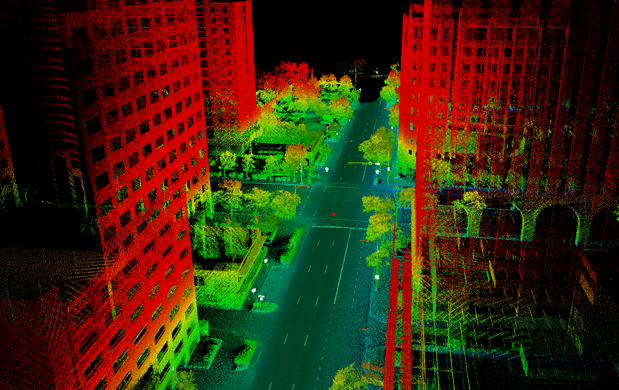

Urban Modeling

Mandli's LiDAR data collection system is an excellent tool for providing accurate models of urban areas. These models can be used to plan improvements, inventory assets, and evaluate civil concerns. The LiDAR data is easy to collect and update, providing a realistic representation of the urban environment that is three-dimensional and fully interactive. All buildings, objects, and roadway assets that are viewable from the street can be clearly seen in the post-processing software. These objects can be extracted and tagged to maintain an easy-to-use and accessible database of urban assets.- Plan improvements, inventory assets and evaluate civil concerns

- Fully interactive model

- Create customized databases

Asset Inventory

Mandli's LIDAR, imaging, and positional data can used to extract relevant assets from collected highway data. All assets can be referenced to the GPS and right-of-way imaging data. Customized databases can be used to record characteristics for many different types of assets, and can include the number of assets in a particular area, their dimensions, and a photo reference of the selected assets. Sample assets that can be extracted include:- Trees, Non-Breakaway Poles and Walls

- Shoulder Slope

- Shoulder and Lane Width

- Roadway Slope

- Curvature

- Super Elevation

- Passing Areas, Acceleration, and Deceleration Lanes

- Acres of Landscape, Wildflowers, and Mowing Limits

- Asphalt and Concrete Lane Miles

- Asphalt and Concrete Shoulder Miles

- Fences

- Attenuators

- Delineators

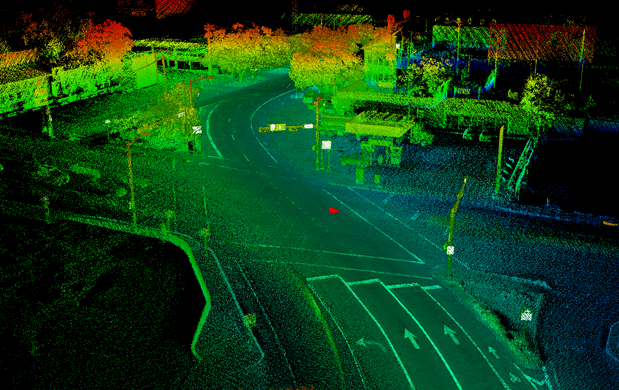

Intersection Modeling

Railroad and street intersections can be some of the most dangerous areas on the road. Using our LiDAR and imaging systems, Mandli can reproduce a realistic and accurate representation of these intersections, including everything seen by train operators, motorists, and pedestrians. Full and partial obstructions of the tracks and streets, as well as location of signage and pedestrian walkways, are all clearly visible. An interactive archive of railroad conditions including field of view and signage is useful for making safety improvements, sorting out legal issues, and as a visual verification of existing data reports. Our combination of LiDAR and imaging data provides a complete view of each crossing, making it more useful than standard image collection alone.- Fully interactive model of intersection created with LiDAR data

- Recreated views of motorists, train operators, and pedestrians

- Useful tool for making safety improvements

Asset Encroachment

Power lines are often a difficult, time consuming, and hazardous asset to inventory manually. With Mandli's LiDAR data collection system, power lines and surrounding vegetation can be automatically catalogued. The data can be used to display the number of power lines present, the physical proximity between the individual lines, and the proximity from the power lines to the road. A frequent cause of power outages is vegetation encroachment on suspended power lines. Vegetation density and distance can also be measured and outputted in a convenient format.- Inventory power lines quickly and easily

- Identify problem areas for vegetation encroachment

- Create customized databases from the information

Right-of-Way Imaging

Mandli's right-of-way imaging system is capable of recording digital images and data in a variety of weather, speed, and lighting conditions. The imaging software controls data collection with real-time image viewing, camera controls, GPS data, route setup and management features, and DMI calibration and operation. To ensure that high-quality images are collected, the software provides preset and manual camera settings for various lighting controls. The cameras are also able to adjust to different lightning conditions in order to capture quality images in both high and low light environments.- Real-time monitoring of image collection

- Frame rate ranges from 100 to 500 images per mile

- System operational at speeds ranging from 0 to 70 mph

- Images are referenced to linear distance traveled (DMI) and DGPS information

- Images compressed in JPEG format

- Camera resolution ranges up to 3296 x 2472 pixels

Curve and Grade

Mandli's positional system uses differential GPS and an inertial measurement unit (IMU) to extrapolate road geometry such as curve, grade, and cross-slope. The vertical grade (slope) and horizontal grade (cross-slope) are standard outputs from Mandli’s POS LV system. They are also referenced as pitch and roll respectively. Due to the fact that these measurements come directly from the inertial sensor, they are highly accurate and reliable.- Curve can be calculated using a chord or an arc length as set by the user

- Grade values are outputted as percent

- Curve and grade classes are fully customizable

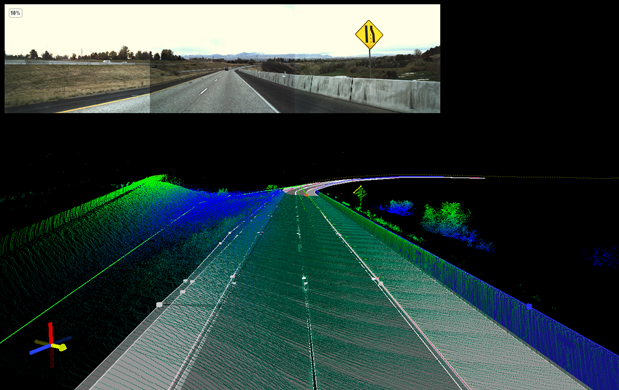

Real-Time Differential GPS

Position, velocity, attitude, track, speed, and dynamics are all collected from a moving vehicle with Mandli’s positional system. The data provides motion compensation information to other sensor systems onboard the data collection vehicle, and is used to create centerline maps and calculate geometric data such as curvature, grade, and cross-slope. The DGPS information provides real-time corrections to the vehicle by utilizing permanent base stations located throughout the continental United States.

Mandli’s system includes an Inertial Measurement Unit (IMU) with real-time differential, and a wheel encoder Distance Measurement Instrument (DMI) that provides a measure of the vehicle’s linear distance traveled, and is used to constrain errors in vehicle velocity and displacement.

- Collect positional data for motion compensation information and centerline map creation

- Utilizes IMU and wheel-encoder DMI

- Able to extrapolate road geometry such as curve, grade, and cross-slope

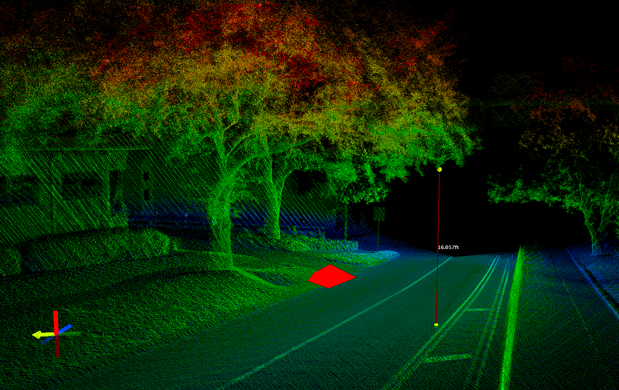

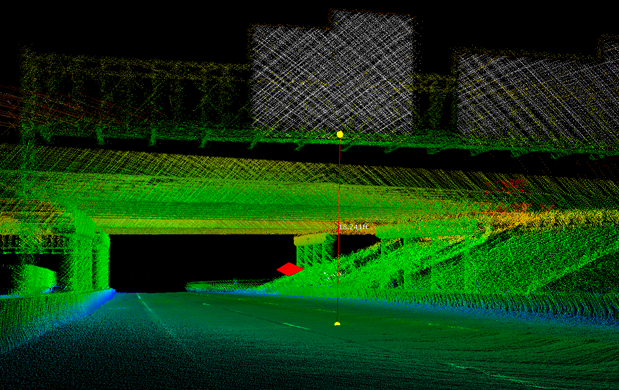

Clearances

Overhead clearances are often difficult, time consuming, and hazardous to inventory manually. With Mandli’s LiDAR data collection possible obstructions, such as power lines and vegetation, can be automatically identified and extracted. The data can be used to display the number of obstructions present, the physical proximity between them, and the proximity from the obstructions to the road. Attributes such as vegetation density and distance can also be measured and outputted in a convenient format.

- Measurement of both vertical and horizontal clearances

- Automatic identification of objects hanging over roadway

- Able to measure density of vegetation

Sign Retroreflectivity Data

Mandli's mobile RetroView system allows for the collection of retroreflectivity data from a moving vehicle traveling within the flow of traffic. The system provides a fast and safe method of collection; no personnel are required to exit the vehicle at any time to measure sign attributes, reducing the risk of injury to both the working personnel and the traveling public.

Other retroreflectivity measurement methods do not provide the advantages of RetroView. Nighttime sign inspections lack accuracy and provide no data for quality assurance. Handheld retroreflectometers are a slow method of data collection, and often put personnel in hazardous positions. Blanket sign replacements are not cost effective and do not produce an accurate sign inventory.

Mandli's RetroView system provides solid data as to the state of each individual sign, allowing for the implementation of a precision sign replacement plan. A sign management database can be developed that inventories all of the collected sign inspection data, and includes management tools to track maintenance requirements, schedules, and budgets.

- Collection of retroreflectivity data from a mobile system

- No need for handheld reflectometers or nighttime inspection

- Increases safety of data collection process

Pavement

Distress Analysis | Pavement Data

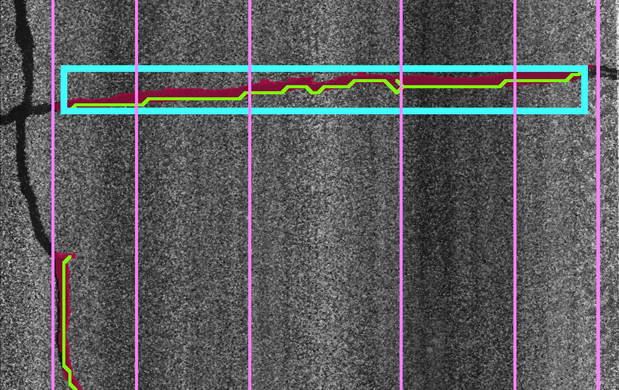

Distress Analysis

An important feature of the pavement management system (PMS) is the ability to accurately determine the condition of the pavement network. The pavement distress condition rating procedure utilized by Mandli follows the Pavement Condition Index (PCI) developed by the U.S. Army Corps of Engineers. The use of PCI on road networks is an accepted method used nation wide and has been formally adopted as a standard procedure by many transportation agencies. The PCI for roads has been published as an ASTM standard, D6433. Calculation of the PCI is based on the results of a visual condition survey in which the distress type, severity, and quantity are identified. The distress data provides insight into the causes of distress whether it is related to load or climate. To determine the condition rating using the PCI method, the pavement is divided into inspection units, which are referred to as “sample units.”

- Developed by the U.S. Army Corps of Engineers

- Published as an ASTM standard, D6433

- Distress type, severity, and quantity are identified

- Pavement is divided into “sample units”

Pavement Data

Mandli is able to collect and process a wide range of pavement data. Transverse profile indexes convey the condition of a road at a specific station and the road characteristics that can be measured from a transverse profile increase with the number of points in the profile. Road conditions, such as the bump in between dual tire ruts or the width of a PCC fault, manifest themselves on the scale of 1" and smaller. Several transverse profile classifications exist for analyzing rutting, a condition which affects aging AC roads to varying degrees. Each index indicates a different feature of the transverse profile, and many correspond to road wear and decay. A goal of continuous research in this area has been to correlate these indicators to maintenance and replacement schedules. Indicators like International Ride Index and Ride Number (IRI and RN) attempt to quantify the ride quality of roads.

- Full spectrum of pavement data analysis available

- Transverse profile information can be processed including rutting, faulting, crossfall, and shoulder drop-off

- Longitudinal profile and IRI data can be easily collected

Bridge

Overhead Signs | Vertical and Horizontal Clearance

Overhead Signs

Overhead sign information can be identified and extracted from LiDAR data using Mandli’s post-processing software. This information can be used to create a custom sign database, and can be synchronized with imaging and positional data for a comprehensive data set. Attributes such as size, type, and mount type can be easily identified using the LiDAR data attributes. Location and legend information are also available with the full data set. Clearance information is yet another valuable measurement which can be produced by analyzing the LiDAR data.

- Data used to create custom sign database

- Features such as condition and sign mount type extracted

- Synchronized imaging and GPS data provide location and legend for sign

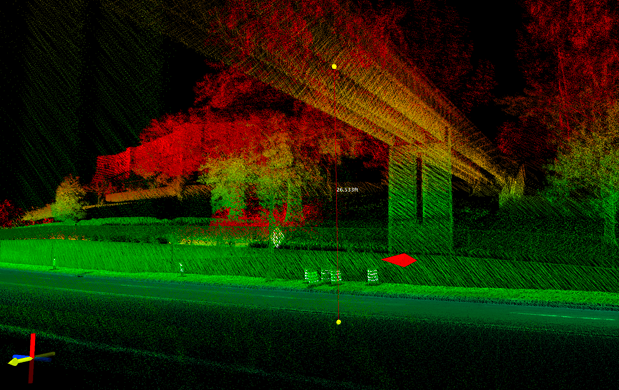

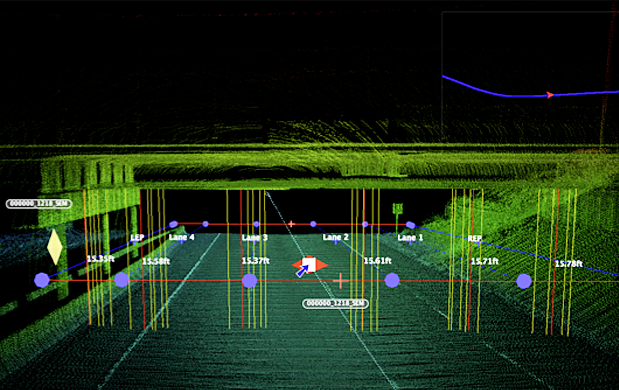

Vertical and Horizontal Clearance

Currently, many organizations utilize manual methods to measure vertical and horizontal bridge clearances. Not only is this time consuming, but also costly and dangerous, compromising the safety of employees as well as passing motorists. Poor or inaccurate data can cause damage to vehicles and highway structures. Conversely, overly conservative routing inhibits economic activity and provides the impetus for unauthorized route modifications. Mandli’s LiDAR system provides a far superior method to older collection practices. The LiDAR sensors collect a point cloud of data, scanning the roadway and surrounding environment. Mandli’s software takes this point cloud and analyzes it for bridge data, extracting the vertical and horizontal clearance measurements. The system provides a cost-effective means of collecting this important dataset in a single pass at highway speeds.

Engineering

Energy | Military Installation

Energy

Pavement damage liability is a growing concern for those involved in industries that require the repeated transport of large loads over federal, state, and local roads. Mandli offers a comprehensive solution to such organizations that are concerned about being held responsible for costly pavement repairs. Using a vehicular-based data collection system, Mandli is able to collect pavement condition data for every road involved with the project both before the beginning of the transportation phase, and after the project is completed. Then, Mandli is able to provide an analysis of the data showing how much damage, if any, the transporting organization caused, and estimate what any repairs would cost.

- Initial pavement data collection phase before the transportation of materials and equipment begins

- Optional mid-project data collection phase to ascertain if any pavement damage has occured

- Final data collection phase to gather all pavement condition data after the project is completed

- Pavement data comparison performed by Mandli

Military Installation

Mandli is able to deploy a data collection vehicle anytime during the year to collect a complete range of pavement testing data. The systems include high resolution right-of-way imaging, transverse and longitudinal pavement profiles, digital downward imaging, and GPS data. The system can collect automated data in a matter of a few days and can be processed using Mandli software for a pavement management program including PCI and distress ratings. Once the data has been used, it can be archived to use for analysis and comparison for future data collection cycles.

- Day or nighttime collection (excluding right-of-way imaging)

- Consistent data collection in all lighting conditions

- 100% pavement coverage of all roadways or runways

- All data collected and integrated with GPS

- Data can be formatted to fit any pavement management software